Call: 08045817015

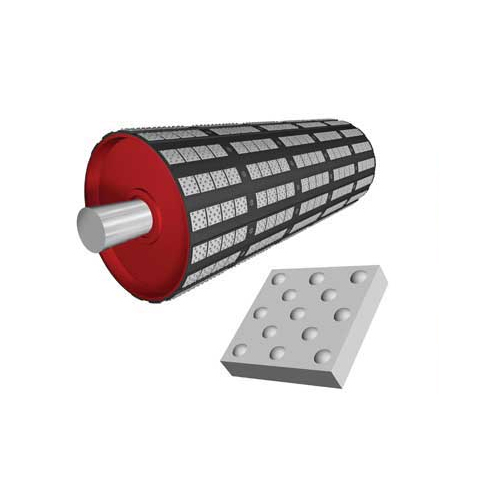

Impact Pads

MOQ : 10 Pieces

Impact Pads Specification

- Features

- Corrosion Resistance

- Surface Finish

- Paint Coated

- Material

- Mild Steel

- Size

- Customized

- Color

- Blue

- Usage & Applications

- Conveyor

Impact Pads Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Impact Pads

Discover our hot-selling Impact Pads, exclusively designed to deliver a lofty standard of protection for conveyor systems. Crafted using premium mild steel and featuring a paint-coated, corrosion-resistant surface, these featured pads are truly a paragon of durability. Ending soon, this gorgeous blue solution fits customized sizes to suit diverse operational needs. As a leading supplier and trader in India, we ensure our impact pads cater to rigorous industrial environments, extending service life and seamless operation. Choose our innovative approach to keep your equipment safeguarded and efficient.

Impact Pads: Tailored Solutions for Conveyor Systems

Impact Pads are engineered to absorb energy and minimize wear in conveyor applications, particularly at loading and transfer points. Preferred by industries seeking advanced protection, they are used by logistics and material handling companies to safeguard both equipment and cargo. The primary advantage lies in their superior energy dissipation, reducing costly downtime and maintenance. With a corrosion-resistant coated surface, these pads are ideal for long-term usage in demanding operational settings.

Export Markets, Packaging, and Pricing of Impact Pads

Our impact pads are supplied and shipped to key international markets, with a strong export presence in Asia and emerging economies. Each unit is securely packaged to ensure integrity during transit, reflecting our commitment to high standards. We offer sample policies for potential buyers aiming to test quality before bulk orders. Seeking the lowest price? Our competitive rates and efficient supply chain make us a top choice among global procurement specialists.

Impact Pads: Tailored Solutions for Conveyor Systems

Impact Pads are engineered to absorb energy and minimize wear in conveyor applications, particularly at loading and transfer points. Preferred by industries seeking advanced protection, they are used by logistics and material handling companies to safeguard both equipment and cargo. The primary advantage lies in their superior energy dissipation, reducing costly downtime and maintenance. With a corrosion-resistant coated surface, these pads are ideal for long-term usage in demanding operational settings.

Export Markets, Packaging, and Pricing of Impact Pads

Our impact pads are supplied and shipped to key international markets, with a strong export presence in Asia and emerging economies. Each unit is securely packaged to ensure integrity during transit, reflecting our commitment to high standards. We offer sample policies for potential buyers aiming to test quality before bulk orders. Seeking the lowest price? Our competitive rates and efficient supply chain make us a top choice among global procurement specialists.

FAQs of Impact Pads:

Q: How are impact pads utilized in conveyor applications?

A: Impact pads are installed at critical points on conveyor systems, typically where materials are loaded or transferred, to absorb shock and reduce wear, prolonging the lifespan of both the conveyor belt and associated machinery.Q: What benefits do the paint-coated, corrosion-resistant surfaces provide?

A: The paint-coated, corrosion-resistant surfaces help protect the mild steel pads from environmental damage, ensuring durability even in challenging industrial conditions and reducing maintenance needs.Q: When is the best time to replace or install new impact pads?

A: Replacing or installing new impact pads is recommended when you notice increased wear, vibration, or material spillage at conveyor transfer points, ensuring continued equipment protection and operational efficiency.Q: Where can these impact pads be supplied or shipped?

A: Our impact pads are supplied and shipped throughout India and exported to various international markets, with strong logistics ensuring timely delivery to your location.Q: What is the process for obtaining samples or placing a bulk order?

A: You may request samples by contacting our sales team and reviewing our sample policy. For bulk orders, we provide customized sizes and packaging to meet your specific operational requirements.Q: How do customized sizes benefit industrial users?

A: Customized sizes allow for precise fitting on diverse conveyor systems, maximizing protective coverage and adapting to different operational environments for enhanced performance and safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Belt Conveyor Components Category

Ceramic Pulley Lagging

Minimum Order Quantity : 10 Pieces

Usage & Applications : Conveyor

Material : Rubber

Features : Wear Resistance

Size : Customized

Scrapers And Spares.

Minimum Order Quantity : 10 Pieces

Usage & Applications : Industrial

Material : Mild Steel

Features : Corrosion Resistance

Size : Customized

Warranty : 1 Year

Skirt Sealing System And Spares

Minimum Order Quantity : 10 Pieces

Usage & Applications : Conveyor

Material : Mild Steel

Features : Corrosion Resistance

Warranty : 1 Year

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry